By Josh Hosen

•

June 14, 2023

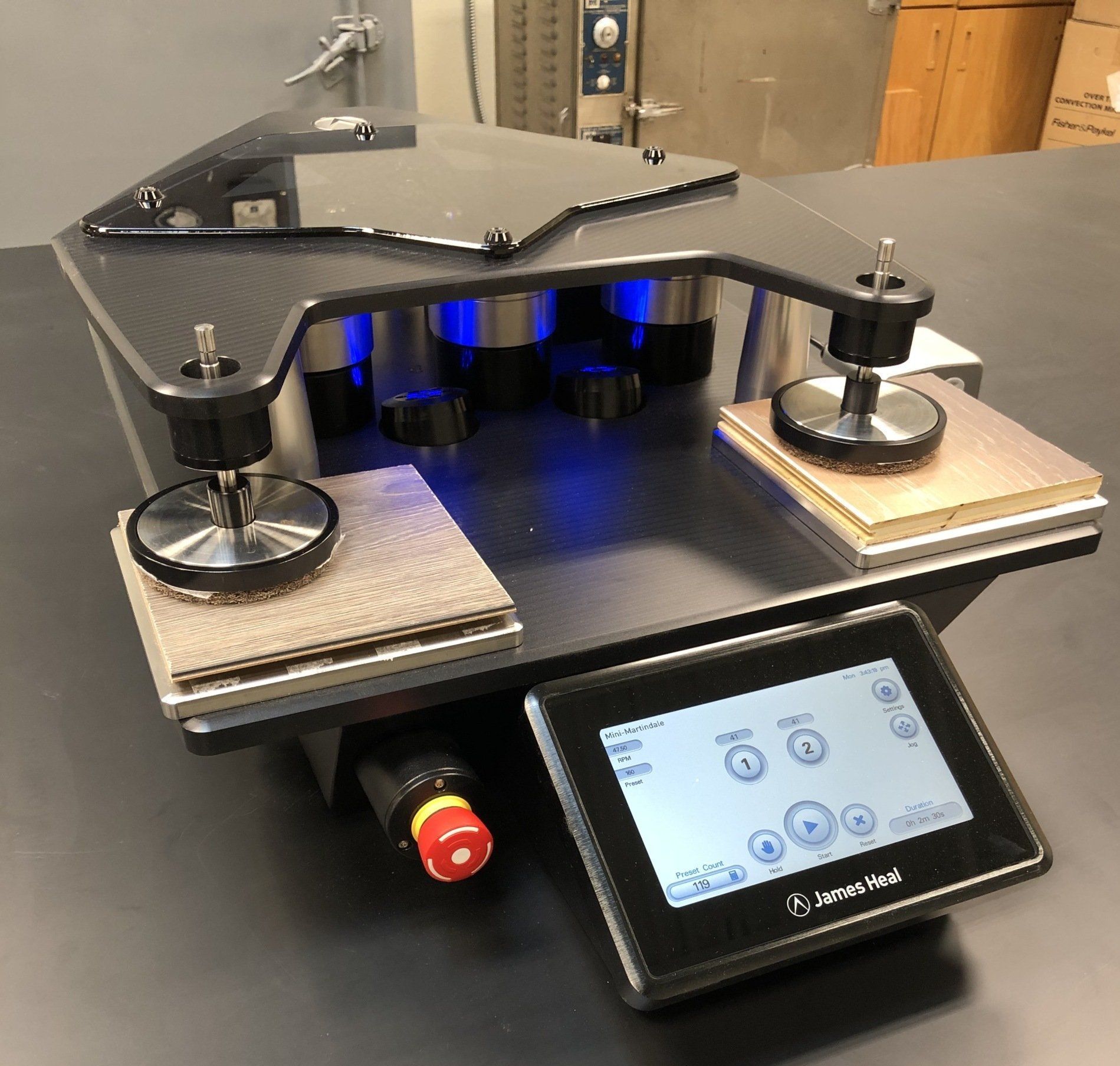

The California Air Resources Board (CARB) will officially stop processing No-Added Formaldehyde (NAF) and Ultra Low-Emitting Formaldehyde (ULEF) Executive Order (E.O., also referred to as "exemption") applications as of July 31st, 2023 . All applications received prior to this date will be processed. T he official CARB announcement can be found on their website here . Historically, CARB has been the primary issuer of new/renewed/amended E.O.'s, and has listed them all in a single, conveniently-located list on their website. CARB-issued E.O.'s have the added benefit of being accepted under the more recent federal regulation governing composite wood product formaldehyde emissions, U.S. EPA TSCA Title VI. TSCA Title VI allows NAF/ULEF exemptions to also be issued by EPA-recognized third party certifiers (TPC's), but certified manufacturers have typically defaulted to using CARB for this service since they do not charge a fee, and many manufacturers had to use them prior to TSCA Title VI going into effect. With CARB no longer processing NAF/ULEF applications, TPC's like Capital Testing will become the only approved providers of these exemptions. With this news comes several questions and concerns: 1.) The TSCA Title VI regulatory language provides little guidance to TPC's on how to process these applications. Additionally, there are discrepancies in what application information is required under CARB vs TSCA Title VI. While CARB indicates they will accept TPC-issued exemptions, this all creates the potential for 33 TPC's to have 33 different applications and application processing procedures, exemption certificates, locations where exemptions are available online (if at all), etc. This lack of standardization could lead to inconsistent application reviews and significant confusion in the marketplace. UPDATED 7/17/2023: EPA has updated the NAF/ULEF section of their FAQ for regulated stakeholders h ere to address several questions regarding the TPC's NAF/ULEF application review and approval process. CARB will also provide NAF/ULEF application review instructions to TPC's prior to the July 31st deadline. 2.) Resin information confidentiality: Currently, CARB is the single entity receiving confidential resin information from dozens of resin suppliers as a requirement of the exemption application process. Now, these suppliers may need to supply this information to up to 33 different entities. This is a substantial confidentiality risk for these suppliers, and potentially for the TPC’s. UPDATED 6/15/2023: EPA indicates they do not expect TPC's to review confidential resin information as part of the NAF/ULEF exemption process. TSCA Title VI only requires identifying the resin system used by the panel manufacturer (e.g. UF, PVA). UPDATED 7/17/2023: CARB indicates they also will not require TPC's to review confidential resin information, however the resin's status as a NAF/ULEF resin will need to be verified with CARB. CARB is working to establish a protocol for this prior to the July 31st deadline. 3.) TPC's willing to issue these exemptions will be taking on substantial liability: they may be handling a significant amount of confidential resin information, and will now be attesting to EPA that every exemption is valid and has been processed appropriately. UPDATED 6/15/2023: EPA indicates they do not expect TPC's to review confidential resin information as part of the NAF/ULEF exemption process. UPDATED 7/17/2023: CARB also indicates this will not be necessary. The liability issue regarding confidential resin information is currently resolved. Capital Testing is in directly communication with CARB and EPA regarding these concerns. TPC's and manufacturers will surely have others in the coming weeks as well. We will update this post with additional comments and answers as we receive them. Once these issues have been resolved and the path forward becomes clear, Capital Testing does intend to offer NAF/ULEF exemption services. For an update on our current status, or if you have any questions on how this change impacts your business, contact Josh Hosen . CARB ATCM 93120 and U.S. EPA TSCA Title VI background In 2009, the California Air Resources Board (CARB), implemented a formaldehyde emissions regulation that limited the emissions of hardwood plywood, particleboard, and medium density fiberboard (MDF) panels manufactured in or sold into California. This regulation is known as CARB ATCM 93120, and was used as a template for the TSCA Title VI federal regulation implemented by the U.S. EPA in 2018. Both regulations require manufacturers of the products listed above to be third-party certified by a CARB-approved/EPA-recognized TPC, which requires regular emissions testing and mill inspections. Both regulations also allow these manufacturers to eventually apply for NAF/ULEF exemption (depending on the type of adhesive used to produce their products), which exempts them from some or all certification requirements.