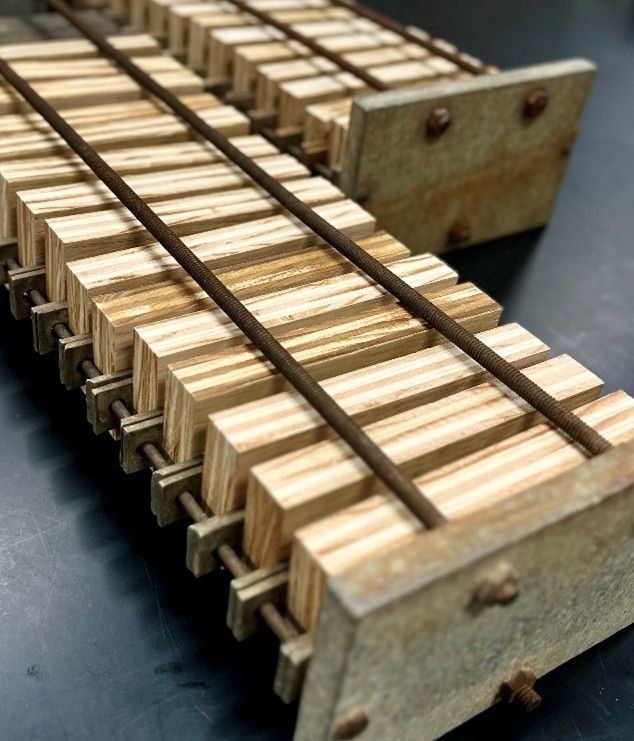

Bondline Delamination Testing

Plywood and Engineered Wood Flooring

Bondline Delamination Testing

Bondline delamination test for interior grade hardwood plywood and engineered wood flooring

Bondline delamination testing, also known as "Three Cycle Soak" or "Type II" testing, is the default test for evaluating the bondline performance of interior grade hardwood plywood and engineered wood flooring. Referenced in the American national standards for hardwood plywood (ANSI/HPVA HP-1-2024 Section 4.6) and engineered wood flooring (ANSI/HPVA EF 2020 Section 4.2), this test method evaluates the adhesive bond quality of these interior grade products by exposing them to three cycles of water submersion and oven-drying. The ANSI standards referenced above contain pass/fail criteria for each product.

Which materials should to be tested for bondline delamination?

Hardwood plywood products claiming compliance with HP-1 type II interior plywood performance (water resistant), and engineered wood flooring products claiming compliance with the ANSI/HPVA EF standard.

What are the sample size requirements?

Hardwood Plywood: a minimum of six test specimens shall be cut from a panel. Typically 10 panels are sampled, yielding a total of 60 specimens for a single test.

Engineered Wood Flooring: two specimens are cut from opposite sides of a plank/product, and tested after all tongue and grooves, or other machined edge portions have been removed. Typically 10 planks are sampled, yielding a total of 20 specimens for a single test.

The dimensions of each specimen is 5" by 2" (127 mm by 50.8 mm), with the length being parallel to the grain of the face veneer.

How is three cycle soak testing performed?

Specimens are submerged in water at a controlled temperature at 24 ± 3˚C (75 ± 5˚F) for 4 hours ± 10 mins and the specimens are then dried in a convection oven at a temperature between 49 and 52˚C (120 and 125˚F) for 19 hours ± 30 minutes with sufficient air circulation to lower the moisture content to 12% or less. The soaking and drying process is repeated three times, completing three cycles. The specimens are inspected for delamination after the first and third cycle.

How do you interpret the results?

A specimen is considered failing when any single delamination between two plies is greater than 2" (50.8 mm) in continuous length, over 1/4" (6.4 mm) in depth at any point, and at least 0.003" (0.08 mm) in width, as determined by a feeler gauge 0.003" (0.08 mm) thick and 1/2" (12.7 mm) wide.

For engineered wood flooring to comply with the EF standard, 95% of the specimens must pass in the first cycle inspection and 85% of the specimens must pass in the third cycle inspection.

For hardwood plywood to comply with the HP-1 standard, it must meet the above criteria in addition to the following: when specimens are cut from multiple panels, five of the six specimens shall pass the first cycle, and four of the six specimens shall pass the third cycle in 90% of the panels tested. Additionally, delamination due to tape at joints of inner plies or defects allowed by the grade shall be disregarded.

Is Capital Testing accredited for this testing?

Yes, Capital Testing and Certification Services is ISO/IEC 17025-accredited to conduct bondline / three cycle soak testing per ANSI/HPVA HP-1 Section 4.6 and ANSI/HPVA EF 2020 Section 4.2. Click here for Capital Testing’s full ISO/IEC 17025 scope of accreditation. Contact experts@capitaltesting.org to discuss your testing needs, or to request a quote!